What is electrical thermal imaging?

Electrical Thermal Imaging detects problematic temperature changes in electrical components, in switchboards and electrical infrastructure. Coopers Electrical provide thermal imaging in Warrnambool and the surrounding district.

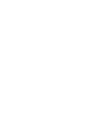

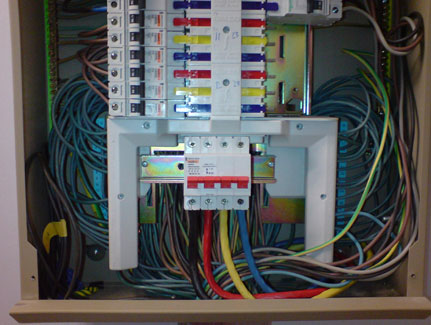

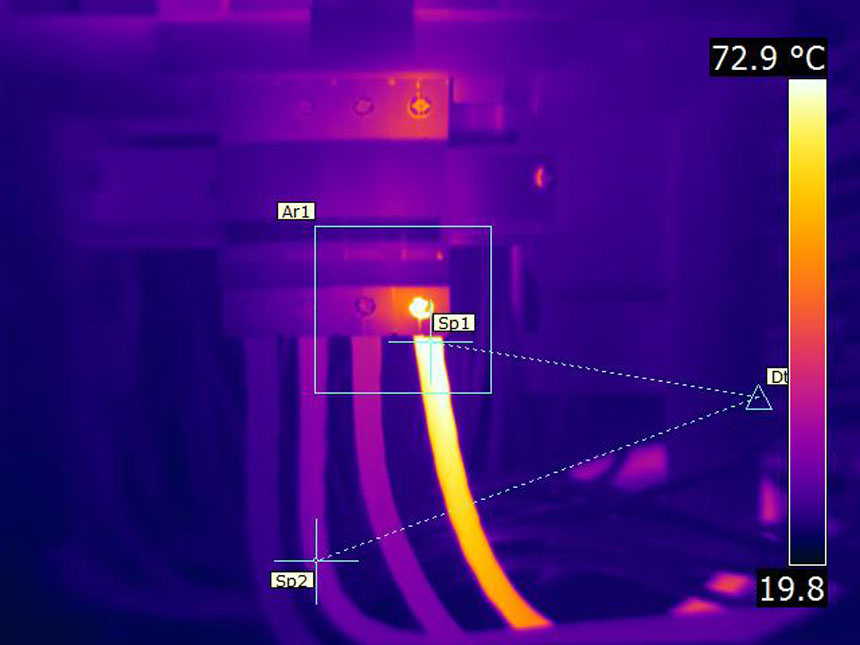

It works using a specialised infrared camera to compare surrounding ambient temperatures against current caring electrical components. This technology allows us to see hot spots caused by faulty electrical components and poor connections. The thermal camera creates an image of the heat providing our electricians with an immediate picture of how the systems are working and any area’s of high resistance across a connection which can result in excessive heat and possible failure, or in extreme cases fire. Changes in heat are represented by a colour scale on the thermographic image.

Thermal imaging uses the latest technology in scanners which can detect electrical faults often missed by traditional methods of testing. Coopers Electrical has years of experience in thermal imaging reporting helping their clients avoid major problems before they occur. Get in touch for all thermal Imaging in Warrnambool and surrounds.

What are the Benefits of Thermal Imaging Testing?

Prevention is better than cure

Regular thermal imaging maintenance checks allow us to see possible electrical failures and potential fire hazards before they occur. Finding these problems early allow preventative maintenance to be scheduled resulting in less expensive breakdowns. At Coopers Electrical we focus on having a preventative maintenance schedule in place for our clients. Thermal imaging is an integral part of these schedules, as the tests actively reduce risk and ultimately save our clients time and money in the long run by detecting faults before they occur.

Test without downtime

One of the great things about thermography is that the scanning is completed without any disruption to production. This means that the tests do not interfere with power supply and that they can be completed whilst equipment is running at normal capacity. As a result you will not experience any business downtime whilst preventative maintenance checks take place.

Heavily reduce the risk of fire

During thermal imaging tests we can identify any hot components, which could mean a loose connection. The early identification of these components means that we can prevent circuits from becoming unbalanced or overloaded. We can also prevent the risk of cables melting and arcing and sparking, which can become a fire hazard.

Thermal imaging compliance checks

Regular checks of switchboards, cabling and switching gear is now a requirement under many statutory regulations and insurance compliance requirements. Intervals at which a thermal survey is required to be conducted, vary according to the building size and range from every 6 months to every 2 years. Coopers Electrical provides thermal imaging in Warrnambool and the surrounding regions providing there clients with full reports along with being able to make appropriate repairs.

How Often Should Thermal Imaging Take Place?

Thermal imaging should be carried out every 12 months at a minimum; however testing should occur more frequently where environmental factors are prevalent